Inventory management is undoubtedly one of the most crucial aspects of any eCommerce order fulfillment process. The entire eCommerce business depends on your inventory management and can often lead to a negative customer experience if not done correctly. Therefore, managing and tracking inventory efficiently is a skill & you need to know all about it to do it effectively.

Did you know that 70% of shoppers would shop for an item at a competitor’s online store if it were unavailable? Most shoppers are not ready to wait for even a day for bank-ordered inventory. With increasing competition, you need to ensure that you do not get left behind. You need to optimize your inventory management to further optimize all fulfillment operations like order management, storage, and logistics.

Inventory reconciliation is one such inventory management component that you need to learn to handle inventory and avoid a stock’s unfortunate conditions efficiently.

With this article, we have briefly explained the concept of inventory reconciliation so you can apply it in your eCommerce business. Let’s get started.

What is Inventory Reconciliation?

How much ever track you keep of your inventory, it is possible that the number of SKUs on the shelf does not match the records. Even though this may seem like a negligible number, it can lead to a massive discrepancy in your overall inventory count.

Inventory reconciliation is the process of comparing physical inventory with the records of the inventory on hand. Even though this process is not very significant every day, it is essential to reduce stock discrepancies and analyze where your inventory control is lacking.

Imagine you are handling thousands of books in a library; you stop them properly on shelves, take a record of the total number, and then compare it with that on your system. If there is a discrepancy in the number, you have to do the whole process again. And if this discrepancy persists, you might be leading your customers to a wrong expectation.

Let’s quickly look at the inventory reconciliation process you must follow when matching physical inventory with inventory records.

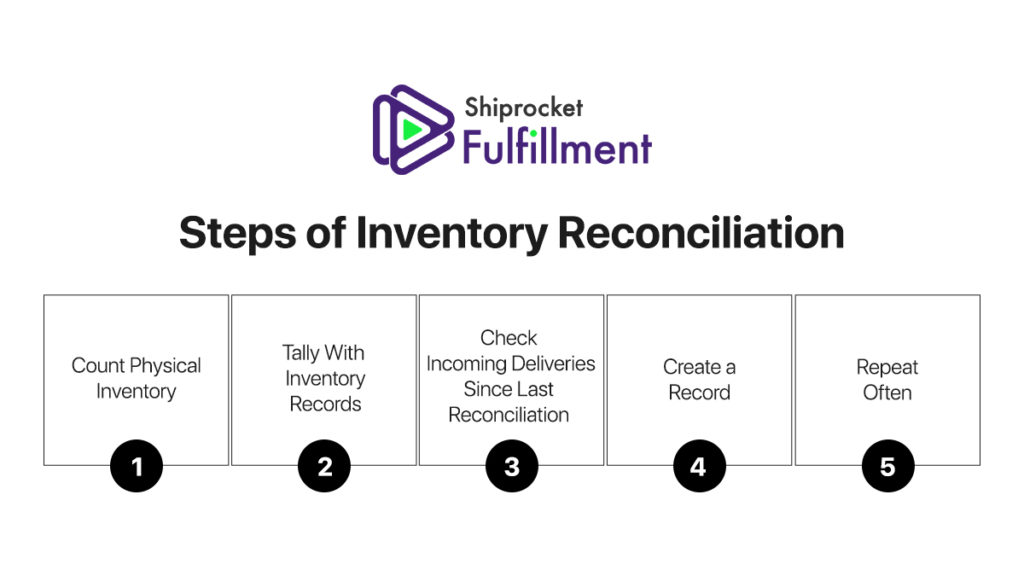

Inventory Reconciliation Process

Even though inventory reconciliation may look like a small check to maintain balance, it is not as easy as tweaking the numbers on your system to match the records; it is as complicated as matching a balance sheet with a left and right equivalent to each other. Therefore, it is recommended to follow this process to reconcile inventory and maintain a thorough check.

Step 1 – Count Physical Inventory

The first step of the process is to count the physical inventory. This should be done before looking into your actual records. If you look at your physical inventory after looking at your existing records, you will subconsciously try to match them, leading to errors.

You must run this through two or three times to ensure no errors, and nobody is missing out or miscounting the inventory. This is even more essential if you have split inventory across different locations.

Step 2 – Tally With Inventory Records

The next step is tallying the numbers with your inventory records. This does not mean telling the overall numbers but matching each physical inventory with the existing inventory records. This is where you will identify where the discrepancies exist. The difference in both values could be due to missing paperwork, human errors, unlisted items, supplier fraud, or scrap items.

Even though this process is slightly time-consuming, you need to examine all possibilities to identify the cause’s root.

Step 3 – Check Incoming Deliveries Since Last Reconciliation

The third step is to look back and see if there were any discrepancies found in the previous inventory reconciliation conducted. Furthermore, look into the delivery and sales records to see if there is any number or an SKU missed out. This will help you explain the discrepancy and also confirm how you can be more careful further on. In most cases, if there are no records like a shipment receipt, signed document, etc., to explain the error, it could be a case of theft or fraud.

Step 4 – Create a Record

Creating a record of the discrepancies identified is one of the most crucial steps. This will help you stay informed the next time you conduct an inventory reconciliation. You can do this with an inventory management system or on a simple spreadsheet using Excel.

Step 5 – Repeat Often

If you believe you need to do inventory reconciliation only once, you are mistaken. You will have to reconcile your inventory whenever you see a new stock to thoroughly check and maintain what is on your shelves along with the records that you store. Hence, conduct inventory reconciliation regularly and maintain thorough records of what you find.

When Must You Conduct Inventory Reconciliation?

Objectively, you can conduct an infantry reconciliation exercise on any occasion. But we would recommend the following –

Seasonal Inventory Reconciliation

This means that you conduct the practice of inventory reconciliation every season based on your demand. This means if you sell winter coats, you will run an inventory reconciliation exercise after the end of summer to check if you have ample winter coats for the upcoming winter season. This is most suitable for seasonal products that are not usually sold all around the year.

ABC Technique

The ABC technique involves segregating the inventory based on the value of the SKUs and the sales volume. You can prioritize the inventory reconciliation practice basis of the revenue and reconcile the inventory based on the category.

Random

With a random technique, you can reconcile inventory whenever you deem fit. It could be twice a year, once a year, or when you discover a discrepancy.

Advantages of Inventory Reconciliation

- Avoid stockouts

- Be aware of theft or fraud.

- Stay up to date with your inventory.

- Accurate demand forecasting

Outsource Inventory Management to 3PL Fulfillment Providers

Efficiently managing inventory can be tedious if you do not do it regularly. Since many DTC businesses are coming up in the country, it can get challenging to manage stocks and also cater to other facets of your business with equal attention. Therefore, it is recommended that you also share inventory management with 3PL fulfillment providers like Shiprocket Fulfillment.

With Shiprocket Fulfillment, you can story or inventory in thoroughly equipped 3PL fulfillment centers located across all major zones in the country. After you send your inventory to us, we will take care of all the processes like inventory management, order management, logistics, and return management. We will handle even tiny components like inventory reconciliation. You can thoroughly outsource a significant chunk of your business and sell peacefully online.

By outsourcing your inventory management and fulfillment operations, you will be able to deliver 3X faster to customers as your store products closer to them. You can reduce fulfillment costs by up to 20% by reducing the warehouse’s distance and the customer’s doorstep. Not just this, you can also reduce your weight discrepancy issues and ship hassle-free with multiple courier partners.

Final Thoughts

Even though inventory reconciliation might seem like a small aspect of a vast inventory management chain, it is equally essential as it tells you about the minor discrepancies in your system. Do not take it lightly and regularly perform to ensure that you do not miss out on the little details.