Picking and Packing Explained: A Beginner’s Guide

Efficient logistics is at the heart of every successful and perfectly aligned supply chain. And two hyper essential processes that keep...

How to Tackle The Common Shipping Problems Effectively

Businesses need more than quality products and marketing strategies to impress customers in this digital era. How quickly and efficiently you...

Top Warehouse Companies in Mumbai: Features & Tech to Consider

Choosing the right warehouse company in Mumbai is key to managing your storage and distribution effectively. With Mumbai’s fast-paced business environment,...

Simplified Returns: The Importance of Return Labels and How to Create Them?

As more and more customers turn to eCommerce, analysts expect ‘return’ rates to increase along. In 2022, the eCommerce return rate...

Why Demand Estimation is Crucial for Your Online Business?

Running a business is a tedious task. You never know how it will turn out in the coming month or year....

Trusted Logistics Companies in Rajkot

Rajkot is a vibrant city in Gujarat with many thriving eCommerce businesses. These businesses require top-class logistics services to deliver their...

Top Logistics Companies in Vadodara

When it comes to delivering products to merchants and consumers, it is more than just placing packages into trucks and ships....

An Insight into Inventory Accounting

Inventory forms one of the most crucial elements of a business’s trading (profit and loss) account and a balance sheet’s current...

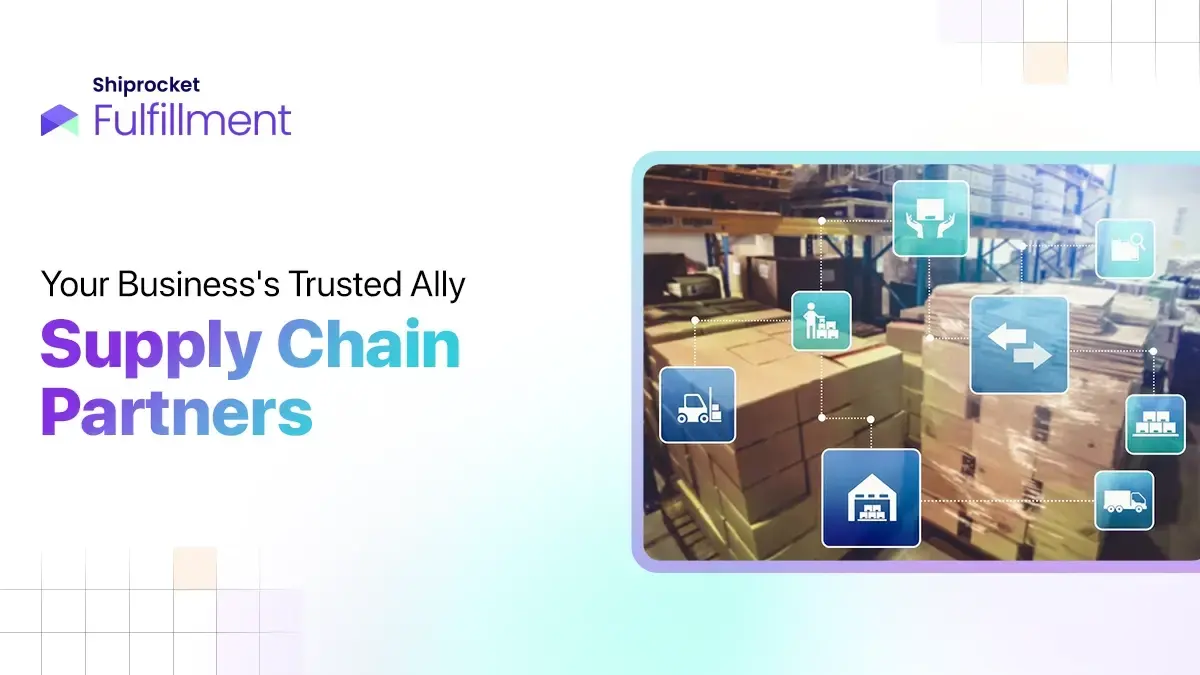

Supply Chain Partners: Beneficial Companions of a Business

Running an eCommerce business involves dealing with many stages and connections in the supply chain, which can get tricky. When things...

Warehouse Operations – The Activities Inside the Process

A set of procedures and activities known as warehouse operations make sure that items enter and exit the warehouse without any...

Subscribe to

Shiprocket newsletter

Get a callback from our expert within minutes