India is a country with diverse climates. In a few country regions, the temperatures can go as high as 45°c in summer and as low as -15°c. Does this pose a drawback for the logistics system? Yes, it’s a drawback. So how can you expect your orders to be delivered correctly at all times? It is with cold chain logistics.

We all have seen milk transported in cold chains across the country in huge containers. But it is not just limited to milk. Several electronics, cosmetics, and other perishable items also need to be transported in cold chains to maintain the quality to reach the customer.

Even though shipping and transportation might be a new concept, temperature-sensitive products have always been transported seamlessly. For example, dairy products were always transported from the rural areas to the urban areas to be sold, and frozen meat was sent to France, etc. Cold chain logistics has always been an essential aspect of eCommerce and trade.

Let’s look at what cold chain logistics is, its importance in eCommerce, the challenges faced, and how you can overcome these challenges.

What is Cold Chain Logistics?

Cold chain logistics refers to the shipping and transportation of temperature-sensitive goods and products in the supply chain. It is the use of technology and science to maintain the temperature and perishability of the products.

Importance of Cold Chain Logistics

Cold chain logistics is integral for the eCommerce supply chain as it helps in the safe transportation of perishable goods. Most perishable goods transported via traditional transportation methods pose a higher risk of a foodborne illness than those transported via cold chain logistics.

Several cosmetic items tend to lose their texture and formulation if exposed to high-temperature. The same goes for pharmaceutical products. It is essential to utilize a cold chain logistic supply chain to transport them safely.

Components of Cold Chain Logistics

Cold chain logistics utilizes several technologies to successfully ship and deliver your products. The different aspects of a cold chain logistics supply chain include –

- Cold storage – This is where the products are stored before being transported.

- Cooling systems include specific temperature control systems that help keep the products at appropriate temperatures during all operations.

- Cold transport – This ensures that temperature-sensitive products are transported appropriately in a cool environment with the correct temperature and humidity levels.

- Cold processing – Facilities and operations that allow for processing goods with the correct temperature in humidity levels and sanitation.

- Cold distribution – Delivery of goods in boxes, crates, pallets, etc., to distribute goods.

Several technologies are used to ensure all these operations are carried out seamlessly in a cold chain logistics supply chain. A few of these technologies include-

- Gel packs

- Dry ice

- Liquid nitrogen

- Eutectic plates

- Reefers

- Quilts

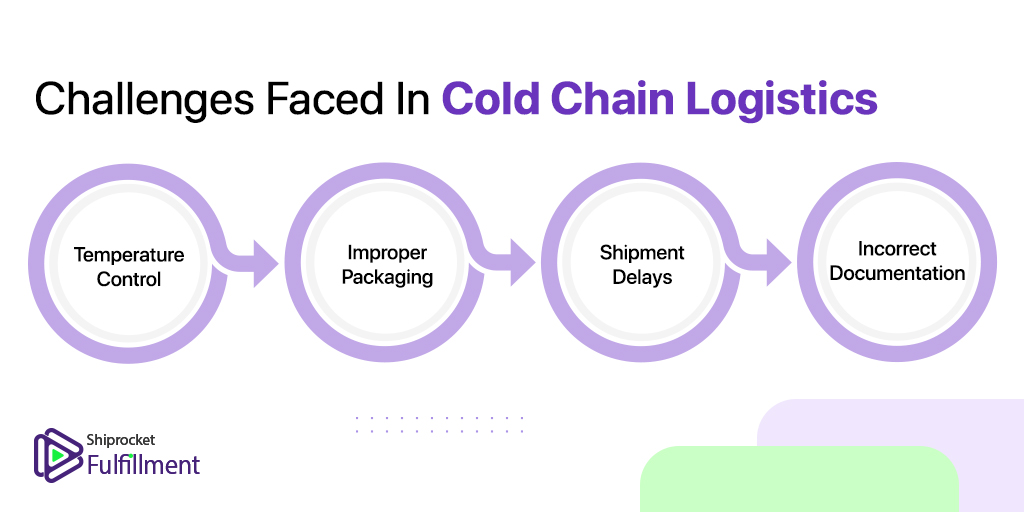

Challenges Faced in Cold Chain Logistics

Temperature Control

Temperature control is one of the biggest challenges in cold chain logistics. Maintaining the correct temperature can be difficult owing to the different weather conditions. Adequate systems need to ensure humidity and temperature control. Also, thorough insulation needs to be installed to restrict outside air.

Improper Packaging

More often than not, improper packaging poses an issue and cold chain logistics. Goods need to be packed inadequately insulated packages to maintain the temperature they are kept in. If the packaging is damaged during transit, it can contaminate the product. Therefore, the product packaging must be sturdy and include a secondary or tertiary layer.

Shipment Delays

If there are shipment delays, it can impact the item’s freshness. Cold chain logistics need to be carried out in strict time frames to ensure no delays to maintain the freshness and quality of the product.

Incorrect Documentation

In cold chain logistics supply chain management, all stakeholders must be aware of the products being transported in the conditions they are being transported in. Therefore, incorrect documentation can cause many issues if even one stakeholder is left out of the picture. Thorough documentation and the proper standard operating procedures are crucial for successfully running cold chain logistics.

How Can 3PL Fulfillment Providers Overcome These Challenges?

Even if you have solid cold chain logistics at your disposal, shipment delays are a common problem owing to the last mile challenges in the country. This is where 3PL fulfillment providers like Shiprocket Fulfillment come into the picture.

Shiprocket Fulfillment offers you temperature-controlled warehousing to ensure that you can store your products at the right temperature in humidity conditions. We will take care of all the order processing and shipping for you. The best part is that you can outsource your fulfillment operations and store products closer to customers. This helps you tackle several challenges at once. Along with saving you shipping and fulfillment costs, it can also help you eliminate the quality issues arising from shipment delays.

Final Thoughts

Cold chain logistics is integral in a country like India, where you need to maintain the product quality before it reaches the customer. With varying weather conditions, you cannot avoid the subject. Invest in proper cold chain logistics and 3PL fulfillment providers to help you achieve this.