The retail and eCommerce space is highly dynamic today. Requirements are changing daily, and customer expectations are more volatile than ever. In such cases, every aspect of your business needs to be strengthened if you want to succeed. Since inventory is your biggest asset, you need to have a cushion(preferably in a buffer warehouse) to absorb the impact of any harm. This cushion is what is known as the buffer, and it can help you prevent shortages and delays in the overall supply chain fulfillment process.

With the increasing demands of e-commerce in India, it is essential to have a buffer in your plan to reach out to the maximum number of people and be resourceful. Thus, let’s look at what buffer inventory is, and its role in eCommerce inventory management and supply chain fulfillment operations.

What is Buffer Inventory?

Buffer inventory refers to the safety stock that is a surplus of the inventory stored in a warehouse. This is used as a safety net in an emergency, delays, a supply chain failure, or an unanticipated surge in demand.

The amount of buffer inventory stored is not a random value. It needs to be carefully estimated by keeping in mind the types of products, production date times, historical trends, etc.

A great example of needing a buffer inventory was when everyone ordered hand sanitizers in 2020, just when COVID-19 struck.

Those who had a safety net of their buffer inventory could deal with this surge and focus on mass production of new ones. Others left struggling and had to face the unfortunate condition of a stockout.

Why Do You Need Buffer Inventory?

Buffer inventory acts as a safety cushion for your e-commerce fulfillment supply chain. This buffer inventory is usually stored in a buffer warehouse. Your entire supply chain depends on the amount of inventory that works in synchronization with the incoming orders. However, if you ever face the unfortunate condition of a stock out, you will have to bear additional costs to ensure that your stock is replenished on time. Getting higher sales than expected is good, but if you run out of inventory, it is never good for your business. Even the forecasted demand can be deceptive if you do not account for losses and emergencies.

Moving forward, let’s have a look at some of the techniques using which you can calculate buffer inventory levels for your business.

Tips to Calculate Buffer Inventory Levels

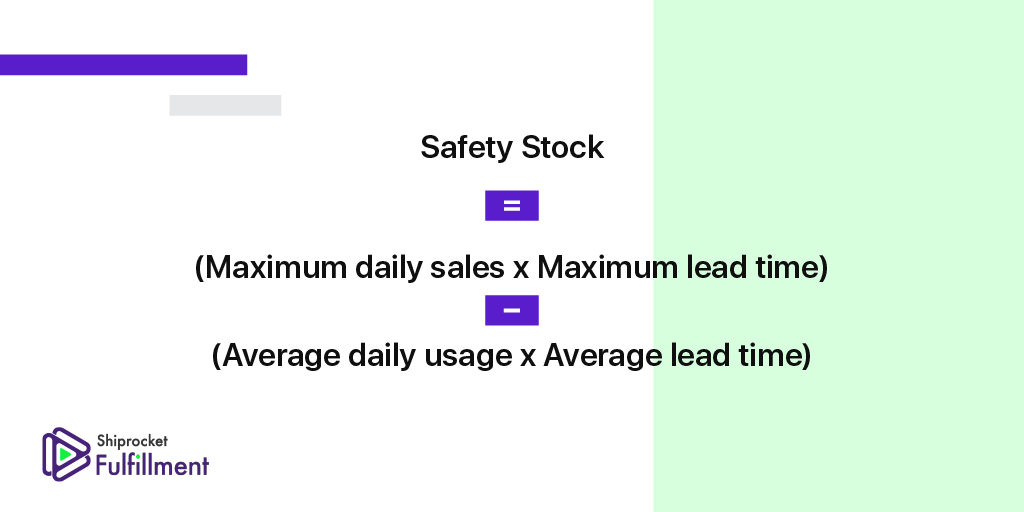

Safety stock calculation

The safety stock formula is excellent for determining the right amount of buffer inventory for your business. You will need to know the maximum daily usage, maximum lead time, average daily usage, and average lead time for calculating this value.

The formula is as follows –

(Maximum daily sales x Maximum lead time) – (Average daily usage x Average lead time)

Historical demand-based buffer inventory

Another technique to calculate the buffer inventory is accessing and assessing historical data by determining the inventory and order data. When you know the inventory turnover rate, SKU performance, and other insights, you will be able to make informed decisions about your safety stock.

How Can You Simplify Inventory Management?

Not just maintaining buffer inventory, but inventory management as a whole can be challenging. It has several minor aspects that need to be catered to daily. Let’s look at how you can simplify our overall inventory management process to ensure maximum yield and results.

Outsource to 3PL Fulfillment Providers

3PL Fulfillment providers like Shiprocket Fulfillment take care of all your eCommerce Fulfillment operations. These operations include inventory management, order management, packing, processing, and shipping. 3PL fulfillment providers have robust inventory management software that can help you significantly improve your forecasting and help improve your sales.

Barcoded Operations

The next step for simplifying your inventory management operations is bar-coded operations. If you add a barcode to your product SKU and the storage bin, it will be easier to locate products within the warehouse, and you will be able to simplify the overall operations. This will help you improve the efficiency of the floor, and your staff will be able to follow a standard operating procedure for every order rather than randomly allocating stuff. Moreover, your inventory management software will function better with regular incoming data that is synced with the products placed on the shelves.

Regular Inventory Valuation

Regular inventory valuation will help you stay on top of the inventory you have the amount of inventory you need. With rich insights, you will strike the perfect balance between the two and avoid situations like the accumulation of debt stock and stockout.

Use Inventory Management Software

Last but not least, it is essential to use inventory management software where you can track and manage inventory from multiple channels. If you have inventory stored in multiple warehouses, inventory management software can be a central point for accessing the data for all these warehouses. This can help you optimize costs and make better decisions when you are planning to meet incoming demand. Furthermore, you can also reduce logistics costs and ensure that you have enough safety stock whenever required.

Conclusion

Having buffer stock is essential for your business since it can help you save on additional order fulfillment costs and give your customer a seamless regular shopping experience without facing any backorders. Like any other safety net, the buffer stock can be beneficial if you want to optimize your operations.