One out of three businesses has missed a shipment deadline because they’ve sold an item that wasn’t in stock. This is the outcome of poor inventory planning and stocking. Such situations are the nightmare of any eCommerce business. That is why it is essential to have the right data to predict the inventory you will require.

This is where inventory forecasting comes into play. With this article, let’s look at what inventory forecasting is and how it is essential for your business. Along with that, we will also look at how you can conduct it for the best results. Let’s dive in and get started.

What is Inventory Forecasting?

Inventory forecasting refers to the process of calculating the inventory required to fulfill customer orders that are about to pour in in the future. This essentially means that you will predict the sales and stock up inventory accordingly. This calculation accounts for historical sales data, promotions, external forces that need to be accurate as possible to give you a specific prediction.

Now, let’s have a look at the benefits of inventory forecasting for your business.

Benefits of Inventory Forecasting

Inventory Estimation

The primary advantage of inventory forecasting is inventory estimation. It tells you the right amount of inventory to purchase. If you do not get a correct estimate of the inventory required, you might store products in bulk in your warehouse, which will eventually lead to debt stock accumulation. This will be too harsh for your inventory carrying cost, and you will have to pay extra for maintaining this inventory or getting rid of it. With inventory estimation due to inventory forecasting, you can help your cash flow and even reallocate resources for other business areas.

Avoid Stock Outs

The next advantage of inventory forecasting is avoiding stockouts. Once you have a precise prediction about the sales you are going to make, you do not have to go through the trauma of an out-of-stock order listed on your website. You can optimize your sales of the existing items without dealing with additional stock or lesser stock. You can also delve further into your marketing campaigns and optimize them channel-wise based on the predictions and supplies you have.

Reduces Overhead Expenses

As you have a correct estimate and forecast your sales and the required inventory, you will save up on many overhead expenses required to manage additional inventory. This will also help you save up on labor and warehousing costs because you are better prepared to handle any changes and reduce manual labor.

Efficient Production and Sourcing

Lastly, with inventory forecasting, you would be able to source inventory better and plan your production more systematically. As you know the production time, receiving times, and the amount of stock you need, you can plan well ahead and stay prepared for the sales.

How is Inventory Forecasting Carried Out?

To forecast inventory, it is essential to know a few variables. Let’s have a look at what they are.

Forecast period

The forecast period refers to the length of time that will be considered to determine the exact inventory quantities. The right forecast period will depend upon your manufacturing production cycle, turnover rate, and sell-out period. It is directly proportional to the time in which you exhaust your inventory.

Trends

Trends referred to the change in demand over a fixed period. So you need to analyze your business’s sales trend and identify periods where sales will be high and low. This way, you can locate your peaks and forecast inventory for definite periods.

Maximum Stock Level

Maximum stock level refers to the amount of inventory you can accommodate for a given SKU. This depends upon the inventory storage space and the funds you have.

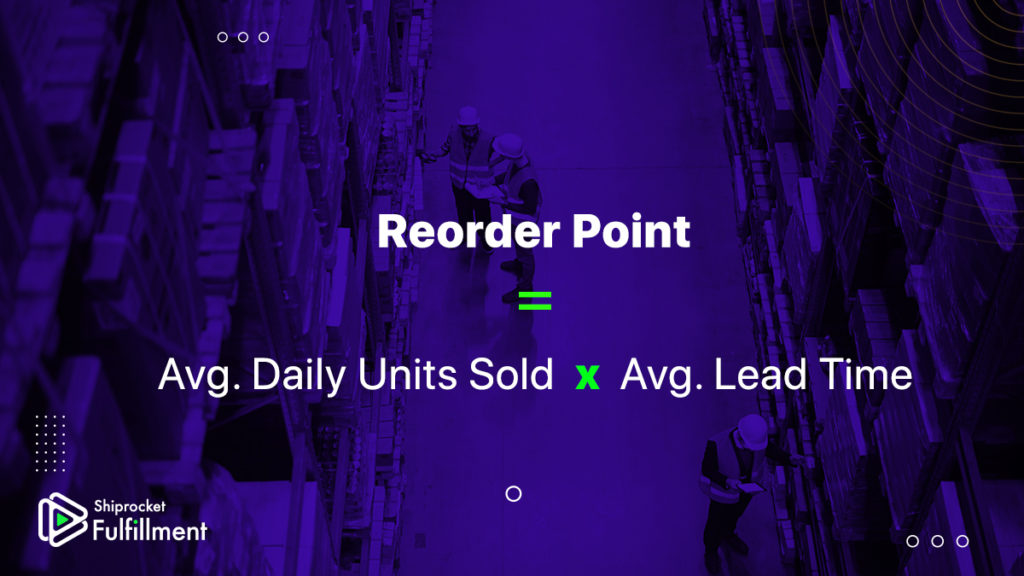

Reorder Point

Reorder point refers to the point at which your stock needs to be replenished. Once you sell your orders, the stock begins depleting. The reorder point is an indicator for you to stock up again.

The reorder point considers the manufacturer’s delivery time, the inventory turnaround time, and the safety stock available.

The reorder point is calculated with the formula that takes into account the reorder quantity for an SKU.

The reorder point formula is –

Optimal Reorder Quantity for an SKU = Avg. Daily Units Sold x Avg. Lead Time

Best Practices for Inventory Forecasting

The best practices for inventory forecasting help you conduct this exercise efficiently. Here are a few best ways to get you started.

Track Inventory in Real-Time

Always track inventory in real-time to have the correct number of SKUs in and out of stock. This will help you estimate your inventory better and faster and give you a more realistic number when forecasting inventory for the future.

Use the Right Software

Using the right inventory management software will help you view the stock levels in real-time and accurately predict future demand. It also gives you several other insights like the most preferred product at which time of the year. Insights like these help you plan better, and you can also optimize your marketing campaigns and forecast inventory!

Gather Insights

Gather insights from how you have made sales in your past quarters and years. This sales and inventory data can be beneficial in guiding you for your future decisions. With rich insights regarding sales, incoming orders, and order processing times, you can be proactive with your choices rather than reactive.

Conclusion

Inventory forecasting is very relevant for eCommerce businesses today. With the fast-paced nature of eCommerce businesses and the sudden rise in demand for online shopping, your business studies must be equipped with the stock levels. One mistake of an out-of-stock item being sold and delayed delivery can lead to a negative customer experience that can be quite harmful to your business.