Warehousing Strategies to Make Your Supply Chain Future-Ready

Warehousing operations are a crucial aspect of a company. Efficient warehousing operations can keep the costs low and customers happy. Whereas, inefficient warehousing operations lead to receiving products late, delayed shipping of products, unproductive workers, and your business losing money and credibility in the market. Therefore, you must have a warehousing strategy in place to keep a tab on all your warehousing functions and operations efficiently.

Warehousing operations play a significant role in the supply chain process, as well. As your business grows, customers demand faster fulfillment and supply chain becomes complicated. But with some warehousing strategies, you can make your supply chain future-ready.

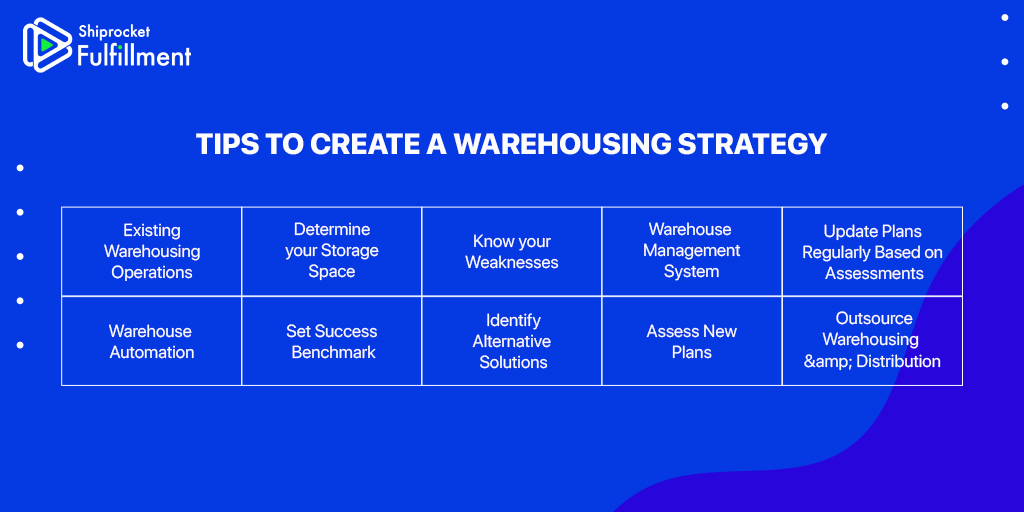

Tips to Create a Warehousing Strategy

Warehousing operations are crucial for the progress of a business. It is imperative that you plan a warehousing strategy to ensure efficient operation and business success.

A warehousing strategy revolves around making critical decisions, such as operation cost and investment, that can decrease the logistics overhead cost. Let us take a look at some tips that can help you create a warehousing strategy effortlessly.

Existing Warehousing Operations

Firstly, look at your current warehousing operations. This is a critical step as it involves looking at the current facilities you have. This step involves creating an accurate sketch of your warehousing floor plan and building. Make sure to maintain accuracy as it will be the base of your future warehousing strategy. You can also manually draw the floor plan by looking at your warehouse.

Write down all the equipment you have in your warehouse. Also, record the number of staff you have and their responsibilities and processes. Look at the procedures you have and then check what is actually happening on your warehouse floor. There is likely to be a discrepancy between what is happening and what should actually be the procedures.

You can also consider interviewing your employee and getting a picture of the warehousing operations. This will help you find out the procedures your staff is using in the warehouse.

This first step of the warehousing strategy is about documenting your warehouse, floor, equipment, processes, and items. You cannot change anything until you don’t know what you actually have.

Determine Your Storage Space

Having what’s happening in your warehouse documented in advance will prepare you to look at your inventory requirements efficiently. This means planning and forecasting the stock you require and determining the warehouse space aptly to store the same.

Consider organizing inventory in the warehouse based on the material and storage traits. When you estimate the inventory requirements, consider thinking about seasonality and high sales value products. You can use previous inventory turnover data to make exact estimates and curate an adequate warehousing strategy.

Know Your Weaknesses

Nobody is perfect! Find the areas and warehousing processes where you can improve operations. The operations notes you made earlier will help you analyze the situation and look for critical areas that require improvements.

Perhaps you may require hiring more staff or upgrading infrastructure to store a certain type of product. To ascertain this, look at the current facilities, processes, and equipment you have. Search for efficient solutions that can help you overcome the warehousing weaknesses.

Warehouse Management System

Warehouse management systems centralize inventory management, shipment planning, product packaging, and order fulfillment. Finding the right management system is crucial to making your warehousing strategy future-ready. If you have the right tools in place, the warehouse management system will help your staff address all the issues that may arise in a timely manner.

A warehouse management system lays the foundation for optimizing labor and warehouse operations before taking a step further toward warehouse automation.

Warehouse Automation

To ensure your supply chain is future-proof, you must opt for warehouse automation. It uses various technologies, including cloud-based applications, conveyor belts, robotics, etc. Warehousing automation helps remove all possible human errors from operations. Automatic tasks can be sorting, packing, and managing inventory.

The following are the benefits that you will get by investing in warehouse automation:

- Increase speed in processing orders and packaging and shipping them to the customers.

- Decreased warehousing operations cost by replacing manual operations with repetitive tasks.

- Optimize warehouse space by reducing human force on a floor and becoming more precise in pallet organization.

Set Success Benchmark

It is imperative to recognize the need for change before it’s too late. This will prepare you for all the situations in advance. If you are always busy addressing your orders, it will turn impossible to get ahead of new technology and business demands. This is why you must set internal benchmarks for your warehousing and distribution.

You can set benchmark goals for individual processes and departments and high-level metrics. This will help you organize everything efficiently. If you notice you struggle to meet the benchmarks, you need to change or upgrade your warehouse operations accordingly. Actively addressing all the performance challenges and overcoming them will help you minimize cost/order.

Identify Alternative Solutions

If things are not working in your favor, think of new and alternative solutions for these problems. You can consider how to improve the warehouse facility, the staff processes, and equipment. Simply look for ways to remove flaws in the ways warehouse operations run.

Assess New Plans

Consider the following points while evaluating your financial plan:

- Total warehousing operation cost

- Tax

- Time value of money

Consider the following when conducting a qualitative analysis:

- Staff safety

- How to easily adjust to changes

- Possibility of inventory damage

Update Plans Regularly Based on Assessments

After making assessments, you must next draft an official warehouse strategy. You must include the following in your strategy:

- Space

- Equipment

- Staff

- Processes

- Future plans

Understand that your strategic plan is always a work in progress, and it will still require amendments. Essentially, you must always keep your strategy updated as you collect data. Updating your plan will also ensure that you are operating efficiently.

Outsource Warehousing and Distribution

The best way to make your supply chain future-ready is to outsource it to third-party logistics. Instead of investing in new technology and changing your warehousing operations, you can outsource your warehousing and distribution operations to a third-party logistics provider.

A 3PL provider takes care of the entire business logistics and offers warehousing, distribution, and fulfillment services. Shiprocket Fulfillment is a 3PL service provider that helps businesses offer one-day and two-day delivery to more than 27000 pin codes through their automated platform.

The Final Say

Warehousing strategy is very critical for improving warehouse efficiency. It helps learn about the suitable floor space, storage equipment, staff, processes, and procedures. With the help of the tips discussed above, you can make your chain supply future-ready.