The eCommerce industry has witnessed an overwhelming increase in the last few years. The worldwide pandemic has further accelerated growth. This has had a direct impact on the logistics and supply chain sector and has led to online sellers adopting different and novel sales strategies, including updating their processes and infrastructure.

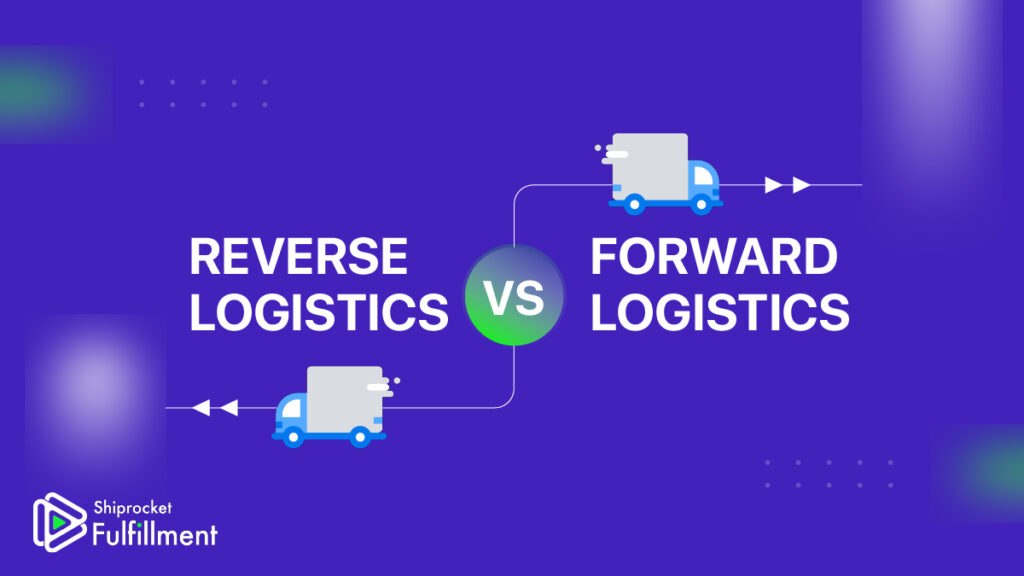

With the entrance of new brands into the market, the competition is at an all-time high. Therefore, online sellers need to simplify their logistics to offer a delightful customer experience and tackle sales well. There is a need for the online sellers to understand the logistics system, as an overburdened system can lead to an unpleasant customer experience. The same can be done by splitting the logistics process into two:

- Forward Logistics

- Reverse Logistics

What is Forward Logistics?

Forward logistics is the traditional logistics where the flow of products is from the factory or manufacturer to the end-consumer. The forward supply chain management includes order fulfillment, hub services, order pick and pack, and shipping to the consumer.

When a product is required, the needed quantity is shipped to the distribution center from the manufacturing or warehousing unit. The products flow to the retail center and, finally, to the end consumers. However, in the case of D2C, the products can directly be shipped to the end-consumers from the warehousing or distribution unit.

The product value increases at every step of forwarding shipping. The farther the final product is from the raw material, the more value it carries. Since a number of intermediaries are present in forwarding shipping, each business tries to maximize its product by adding its margins. However, in the case of a direct-to-consumer business, the intermediaries are fewer. Thus, consumers can procure products at lower costs.

What is Reverse Logistics?

Reverse logistics is the flow of product traveling back to the manufacturer or warehousing unit from the end consumer. The reverse logistics involves product returns, repairs, recalls, and refurbishment. It also includes repacking, restocking, reselling the product, and disposal. By optimizing the logistics process, you can earn long-term benefits for your business by reducing the number of returns.

If a business has streamlined reverse logistics, it can maximize its profits by reducing costs. The reverse logistics supply chain management include:

- Movement of products to the next response – back to warehousing unit

- Removal of product packaging and containers if any

- Destruction of expired pharmaceuticals or expired products

- Returning rejected goods to the supplier

- Entry of the product in the inventory management system

The following are some common reasons for product return:

- Product may be damaged, defective, or expired

- The product is of the wrong size

- Good may be outdated

- Customers may not like product quality

- The product arrived late, and the customer doesn’t need it anymore

- The customer has changed his mind and doesn’t like the product

- The product doesn’t match the description on the website

Thus, while forward logistics is the movement of products from the manufacturing unit or warehousing unit to the consumer, reverse logistics is the movement of goods back from the consumer to the warehousing unit.