There are three inventory management techniques: pull, push, and just-in-time. Depending on the business requirements, a brand manufactures inventory based on customer demand, also known as the pull method. The push method is when a brand pushes out products based on expected demand.

Apart from these two methods, there is a third method, which is our focus in this blog – the just-in-time inventory management method.

What Is Just-In-Time (JIT)?

Just-In-Time or JIT is an inventory management method in which goods are received from suppliers only as and when they are needed. The main objective of this method is to reduce inventory holding costs and increase inventory turnover. Businesses use this method to reduce inventory waste, improve efficiency and have accurate demand planning.

Although the history of JIT traces back to Henry Ford, the American businessman who applied similar principles to manage inventory in the Ford automobile company during the early part of the 20th Century, the origins of JIT as a management strategy track down to Taiichi Ohno of the Toyota manufacturing company.

He developed the just-in-time strategy as a means of competitive advantage during the post-World War II period in Japan.

Just-In-Time Management is also known as Lean Management, Cycle Time Management, Quick Response Manufacturing etc. However, while lean management is a customer-centric philosophy focusing on manufacturing and operations management, JIT has a more business-centric philosophy focused on the production process. Hence, businesses prefer it more as their go-to approach.

How Does Just In Time Work?

JIT inventory management ensures that stock arrives as needed for production or to meet consumer demand, not earlier. The goal is to eliminate waste and increase the efficiency of business operations.

Since the main objective is often quality and not the lowest price, JIT requires long-term contracts with reliable suppliers.

In JIT, the parts of the production or service system are interconnected. These systems exchange information and are mutually dependent on generating successful outcomes. It is a continuous improvement process aiming to streamline the business strategy.

For a successful just-in-time model, a business needs the following:

- Steady & consistent production

- Reliable material suppliers

- Quality systems that work without any fail

- AI-driven accurate demand forecasting

Due to this type of inventory management, businesses require robust network connectivity along with Artificial Intelligence, machine learning, Internet of Things, cloud ERPs, and blockchain technologies to share and analyse data in real-time and make smarter decisions.

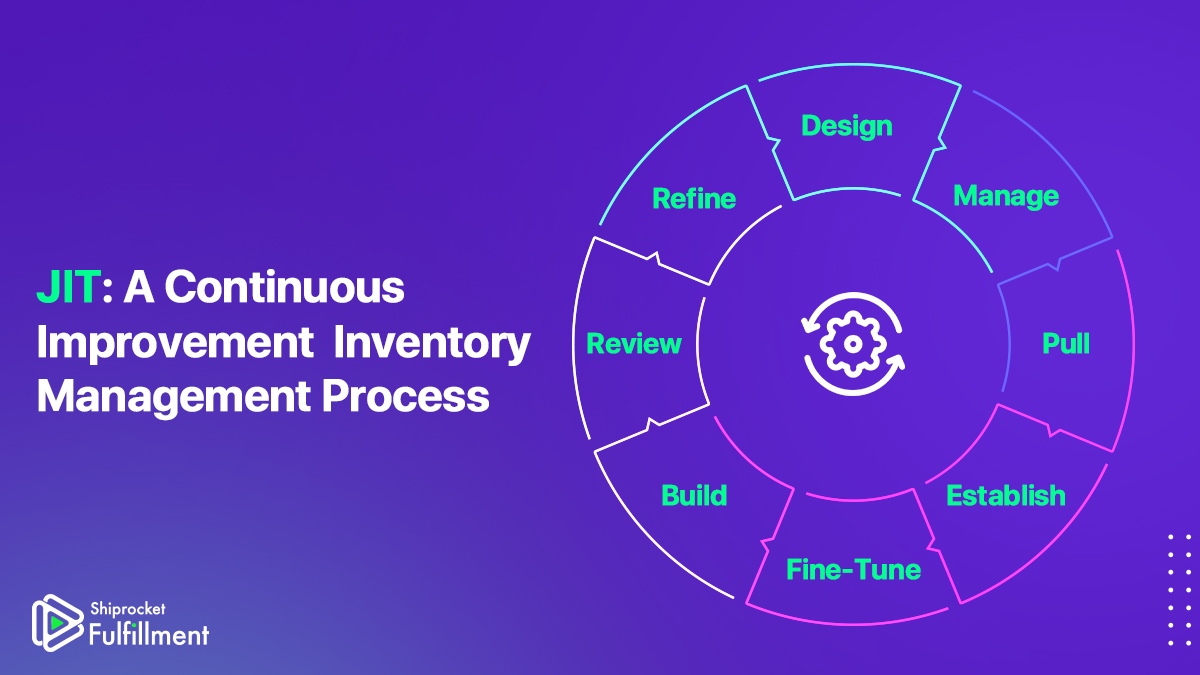

Just-In-Time – A Continuous Improvement Strategy

Since the just-in-time process aims to reduce waste and improve quality, the strategy goes through an 8-step cyclic process for continuous improvement.

- Design: The JIT process begins with a review of the product design, process design, personnel and manufacturing planning to eliminate disruptions, minimise waste & build a flexible system.

- Manage: A Total Quality Management (TQM) review ensures there is continuous improvement throughout the process.

- Pull: The amount and time of material flow are determined by the rate and time of the actual stock consumption. A scheduling system is used for this process.

- Establish: Relationship management is critical in the JIT process. Review your supplier lists. Negotiate contracts, and discuss lead times, delivery expectations and business requirements

- Fine-tune: Determine your inventory needs, brush up on the fine details of policies, and reduce unnecessary inventory movements.

- Build: Inform your team about the skills and capabilities it needs to complete its work and conduct team education and empowerment sessions to educate them. If your business uses automation, ensure the systems are capable of the work required.

- Refine: Reduce the number of steps in production by refining, standardising and reviewing the entire process.

- Review: Define and implement quality measures and metrics and conduct a root cause analysis of any problems. Emphasise improvements and track trends to improve every aspect of JIT.

Advantages Of Just-In-Time Inventory Management

Just-In-Time inventory management has several advantages. It aims to boost a business’s ROI by reducing waste, increasing efficiency and lowering inventory carrying costs.

Some of its other advantages are as follows:

- Gives the manufacturer more control over the manufacturing process.

- Decreases warehouse holding costs and reduces labour costs.

- Reduces obsolete inventory, dead stock & defective product loss.

- Raises inventory turnover ratio and improves local sourcing.

- Minimises raw materials on hand and inventory obsolescence.

- Greater productivity with faster product turnaround with shorter production flow.

Disadvantages Of Just-In-Time Inventory Management

Although JIT has several advantages, there are some disadvantages of the same. The following are the drawbacks of JIT:

- Any disruption in the supply chain can halt the entire production process.

- With no finished goods in hand, businesses cannot address a sudden order surge.

- Shortages and stockouts can disrupt inventory systems.

- There could be forecasting flaws leading to disastrous outcomes.

- Excessive supplier dependence can disrupt the entire supply chain in case of material delivery failure.

Factors To Consider Before Implementing Just In Time

JIT inventory management is not for every business. Every business has its own unique requirements and implements inventory management processes accordingly. Here are six factors to consider before opting for just-in-time inventory management.

- Turnaround Time: Ask if your products can be supplied or manufactured quickly if needed.

- Demand Forecasting: Consider if your business has accurate demand forecasting, even during festive seasons.

- Flexibility: Ensure that your supply chain is flexible enough to adapt to disruptions like supplier drawbacks & natural calamities.

- Distributors: Cross-check if your vendors & distributors are reliable and if your order fulfillment system is efficient enough.

- Workforce: Check if you have multi-functional, cross-trained employees to perform several duties so team members can fill in when and where needed in the production line cell.

- Technology: Check if your business uses inventory management software that supports the JIT inventory system.

Summary

Just-In-Time inventory management is helpful for businesses to manage production and fulfill orders efficiently. They find it beneficial because it reduces waste and helps maintain a positive cash flow. However, there are downfalls to the same. Now that you have an overview of JIT, you can make an informed decision about your business.